The software for counting, measuring and classifying objects. Depending on the optics used, medeaLAB Count&Classify works in the microscopic or macroscopic range. Our software is used in biological and medical research, plant breeding, quality control, and industry, among others.

Count

Our software is used, among other things, to determine germination rates, counting of duckweed (Lemna Test ), quality control of bulk solids (e.g. wood pellets).

Measured

We can measure objects with subpixel accuracy. Various parameters can be determined and evaluated:

Classify

The determined objects can then be divided into classes based on their respective properties, such as homogeneity, form factor or color. This information can be used for further process steps or for a general quality assessment.

Applications

Some examples of the medeaLAB Count&Classify software can be found here…

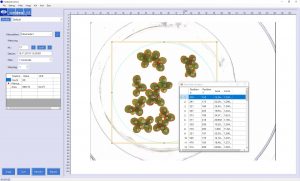

Figure: Evaluation of a water sample for the Lemna test

Figure: Evaluation of a water sample for the Lemna test

Features

Flexible image acquisition

Our software uses image and video files, as well as images from analog, USB, FireWire and GigE cameras or scanners. This makes it easy to integrate into existing systems. Of course, we also supply you with the appropriate image acquisition hardware (cameras, lenses, filters, cables, etc.) if required.

Automatic and interactive threshold setting

In many cases, the system can configure itself automatically. Interactive fine-tuning is facilitated by visual feedback.

Learnable classification

Found objects can be interactively assigned to self-defined classes (learning by example). The automated classification is then performed via statistical classifiers, custom decision trees or neural networks.

Export

MedeaLAB Count&Classify has numerous interfaces for data exchange: clipboard, various file formats, ODBC databases or a convenient automatic export to the MS Office programs Excel or Word via macros.

Reporting

The output of results and graphics can be conveniently done as a report based on supplied or custom HTML templates.

Measured value acquisition

Direct integration into laboratory automation systems is possible via digital I/O, PLC systems or OPC servers.

Timelapse video recording (time-lapse recording)

All video sources of the medeaLAB systems are supported, image intervals from 15 fps to 1 image per hour are possible. Optionally, a triggering by Digital I/O can be done.