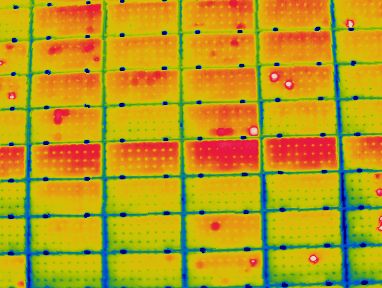

Figure: Infrared false color recording with module defects

With the growing number of installed solar modules, the need for efficient monitoring of the individual solar modules with regard to their functionality is growing. Thus, in this project, infrared thermography images from a flying robot were taken. First the single images taken from the robot needed to be de-warped and stitched together to a combined image. Then, the single solar modules were identified, labelled and processed for quality control.

The medeaLab image processing software was able to detect and locate defect solar modules in solar parks semi-autonomously on the collected images.

Subtasks:

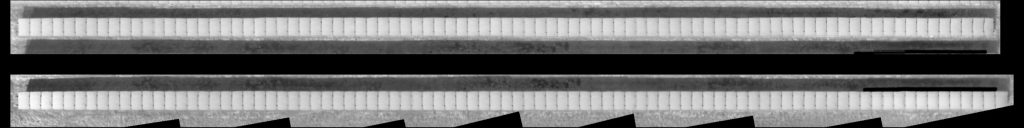

- Creation of overview maps of the solar parks from the image series generated by the flying robot using the thermography camera and color camera.

- Extraction and perspective equalization of individual solar modules from this overview map

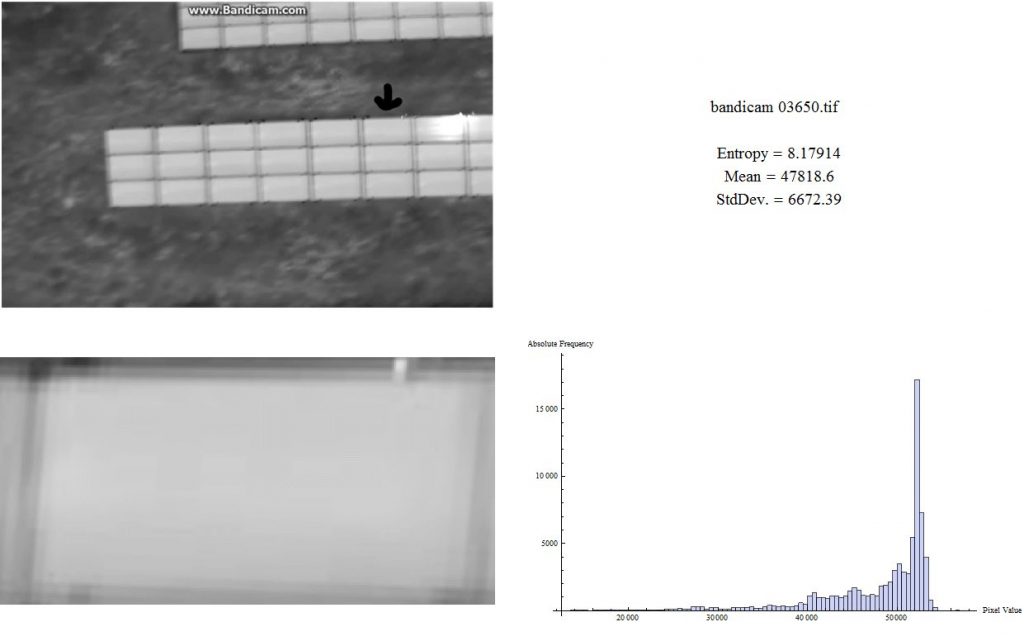

- Manage and select module images for subsequent automated error classification.

Figure: Solar module series assembled from single de-warped images

Figure: Management of flight recordings with module numbers displayed

Figure: Detection of solar reflection (in the overview image center right) on single module images by histogram analysis